The week ahead I was scheduled to haul steel coils loaded suicide from AK Steel in Butler, PA to Norfolk, VA. (suicide is when the coils face the driver – shotgun is when the eyes are facing the driver – thus the danger to other drivers on the road).

With names like “suicide” and “shotgun”, it was apparent that hauling steel coil is risky business.

When you’re hauling steel coils, you cannot stop like other truckers. If a car pulls in front of you and suddenly stops to make a turn causing you to hard brake, the coils can come loose and roll straight into the cab – thus the name suicide.

“How many chains and binders shall I put on her.” I asked my driver manager, Don, as I scanned the load consisting of three huge coils that resembled concrete pipes but many times heavier.

“Build a pair of coil rack and rubber padding for each coil. Then add three chains and binders for each,” Don instructed. “Throw in a strap across the hole for good measure.”

Eventually I just put 10 chains and binders on the load – everything I had I threw on like a cargo ship in port during a massive storm.

“Heck chains and binders weigh just as much on the load as they do in the box, might as well use them,” Don commented.

I remember my trainer warn me last week before I was ready to be released solo.

“If the coils aren’t properly secured with the right chains at the correct angles, and the truck turns a corner too fast, the chains may break and the coils will roll right off. And If a giant 42K lb steel coil falls off a flatbed even a bullet train would not be able to stop it. Cars have been run over and buildings have been smashed by runaway steel coils due to driver error.”

“So why are they coiled in a circle. Won’t it be safer to transport steel flat?” I inquired.

“If it was laid out flat, you would only be able to ship one bundle at a time. As a coil, I’m able to ship several bundles with each load as long as I don’t go past my weight limit,” he responded.

“And why do we have to tarp the coil – after all many of the coils are galvanized steel and stored outdoors at the receiver,” I pressed on.

“Because the customer paid for it to be tarped – that’s why” Don gasped.

“And the reason is to protect the coils from rock, salt, slag and sand, especially during the winter,” my trainer added as he looked at me glaringly.

Don, knew how much I hated tarping on clear sky days. And he knew exactly how to bait me, hook, line and sinker.

“Go get your TWIC card, and I’ll assign you to an account that doesn’t require tarping,” he suggested cunningly.

The TWIC (Transportation Worker Identification Credential) card issued by the TSA and would give me access to the ports, particularly the port of Baltimore.

He didn’t have to say it twice. Climbing on top of the trailer to secure and tarp the load was also inherently dangerous. Another driver at Bowman had fallen off 8 foot off the load and he was laid up for months.

“These port loads from Morimatsu to Proctor & Gamble are already tarped. All you do is have the port jockey forklift the entire bundle onto the flatbed. Then strap it down good with all 10 straps, but not too tight because they’re manufacturing equipment.” Don added, knowing that this would do the trick.

I made my appointment online and the very next week I visited my local TWIC office in Alexandria, VA to get my card. I was ready for my next adventure with the port of Baltimore.

The toughest part of the port loads is getting inside. There’s usually a long line that starts at the crack of dawn. And as expected security was long, drawn-out tough – probably easier to access the pentagon than the ports.

But once I hooked onto the load, it was a smooth sailing to Martinsburg, WV. When I drove into the P&G plant, I was astonished by the size and scale.

“What are you guys building?” I asked in amazement.

“The plant of the future,” the receiver spoke with pride. “All 2.5 million square feet of it.”

A team of 3-4 drivers hauled these loads several times a week. The two-hour drive took us on I-695 to I-70 to I-81 and with plenty of time on the clock.

On 695, I’d drove by Woodlawn, MD twice a day passing Security Square Mall with a couple of large anchor tenants such as Sears and Macy’s. But this wasn’t any typical mall filled with soccer moms in minivans. Big rigs are normally discouraged from parking at malls, but this lot looked more like a truck stop than a shopping plaza. The seven acre mall had dozens of trucks, idling and maneuvering around a maze of cones like an obstacle course. Did I stumble upon a truck driving school in the mall parking lot? What a perfect amalgam. My curiosity got the best of me.

So one day, I decided to take a long lunch and visit the North American Trade Schools. I called ahead and met Melanie, the admissions director who informed me that the diesel mechanic school would be ten months long, and the next class would start at the end of January.

That was just 2 months away – I had to act fast.

“Since you’re already a driver, you’ll bring a whole host of on-the-road experience that others mechanics lack,” Melanie mentioned.

I called my VA Counselor, and in due time, he approved my schooling. Then I called my manager Don – thanked him for the great opportunity, and informed him that I would need a year off from driving trucks to return back to school to repair them. Is this a new fork in the road? Or is this just a means to an end? Where would I park the Prostar that I just purchased and how would I make my daily commute?

Since I was in the twilight of my six-month stint with DM Bowman and since I was from DC, my enterprising company prudently assigned me to a new route that pierced into the heart of the Nation’s Capital.

It was hauling oversized loads from a warehouse in east Baltimore to the much-hyped Quadrangle building in DC. the soon to be a state-of-the-art 12-floor edifice next to the contemporary Warner Theater.

One of the innovative features of the Quadrangle is operable windows to allow fresh air into the elaborate offices. The motorized windows would offer an efficient, sophisticated heating and cooling system. The building’s glass skin, with stainless steel horizontal panels and a vertical steel grill shrewdly work together as an external shading system.

What a sleek building this would be with an elegant skin respecting the tradition of Washington, but in a modern way reminiscent of avant-garde LA.

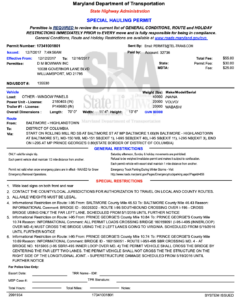

Since the windows were 11.5 feet wide, they were carried as oversized loads requiring a special permit and a specific route that took me all the way down south by the MGM in Oxon Hill, MD and then up 295 into the District. No, I couldn’t take 50 into New York Ave, but I certainly wanted to. Believe it or not, there’s a weigh station on 295, although, I’ve never seen it manned. Oversized trucks would park there from time-to-time before they rolled into the city after the mean morning rush hour.

For once, It was nice to deliver a load into the District and convenient that I could stop home after to check my mail and take a shower before I headed back up to run another load the next day.

I made several trips during the week for three weeks. My fellow trucker, Phillip and I were the only ones who were dedicated to this load. Eventually, I trained another truck driver who rode co-pilot so he could see how we secured and get familiar with the route. My last day at work was fairly uneventful and I turned my truck in at the yard in Frederick, MD. But then I got a text from my driver manager. He asked if I could come to work on Monday. Since I was available, I agreed.

On Monday, after securing the load, I went over the Francis Scott Key bridge on I-695 over the expansive Patapsco River. Normally, I would take the last toll on the right since it was the widest, but today, that lane was backed up by someone not having the right change, so unfortunately my impatience got the best of me. Foolishly, I decided to take the adjacent lane to the left. As soon as I started to proceed, I began to regret my decision. And the impact hit me like a truckload of bricks.

To my dismay that lane was too narrow and my oversized load of 11.5 feet struck the pole that holds the EZPass LED display and bent it like a crooked branch. There was still a chance that I could squeeze through, but at the expense of my load. My instincts told me to stop, and for once I heeded my sub-par intuition.

I held up traffic, scornful drivers who looked glaringly with disgust. Thankfully, The Maryland Transportation Authority was able to turn the display around rather quickly to allow me to go through.

The trooper, a large, brawny man so austere he could intimidate my drill sergeant, instructed me to pull over to the shoulder while he checked my license, registration and permits. And the clock ticked to what seemed like eternity as I made several calls to the Driver Manager and Safety Officer. Neither were pleased, but thankfully both were kind and tactful. I was ready for a severe scolding.

I thought for sure I would be facing a ticket – points, even a fine. But for some strange reasons the sun was shining bright, and the ticket gods were been kind to me that day.

The permit was very explicit in directions from pickup to delivery. It instructed me to take the Key Bridge but did not state which toll lane to take.

“You should have known better,” he scolded. “But since you were just following the letter of the permit, I’ll let you slide this time.”

I smiled and graciously thanked the officer, apologizing in the same breath.

Amazingly, I had lucked out! My last load with DM Bowman was also my first accident with DM Bowman – a small incident, and thankfully I survived relatively unscathed, but my ego bruised.

So I did finally deliver my load, albeit a few hours late. It wasn’t damaged and to this day, you can look up to the top of the Quadrangle building and point out to the window that put a dent in the Francis Scott Key Bridge toll booth. You can’t tell, but I sure got a story to tell.